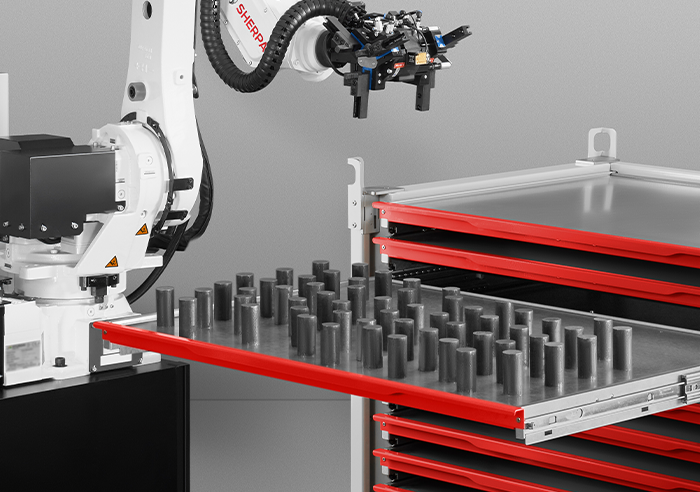

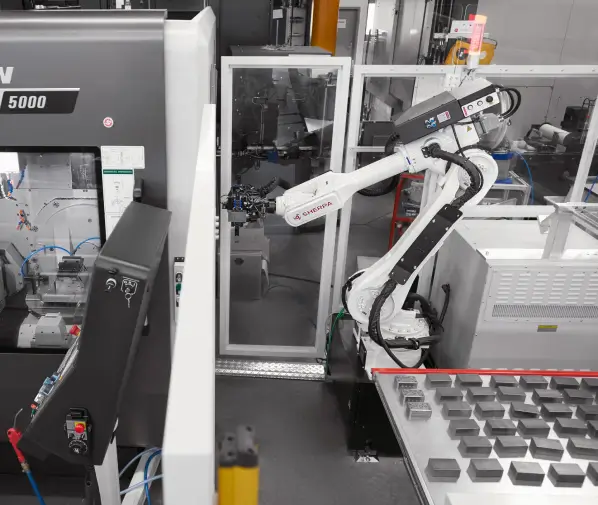

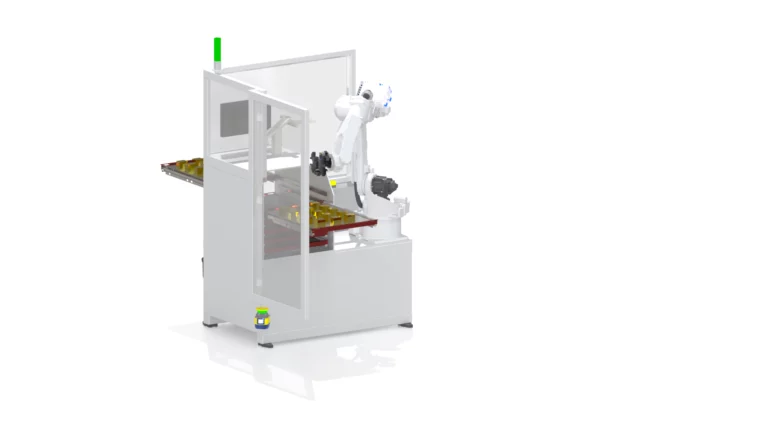

The SherpaLoader® is the world’s first standard CNC loading robot that can automatically identify cylinders, cuboids, and sheet cuttings. Equipped with a camera and laser system, it detects workpieces on table trolleys, drawers, and pallets, picking them up for loading into machine tools. After machining, it removes the finished parts from the machine and places them back onto the loading device.

Learn morePart Recognition

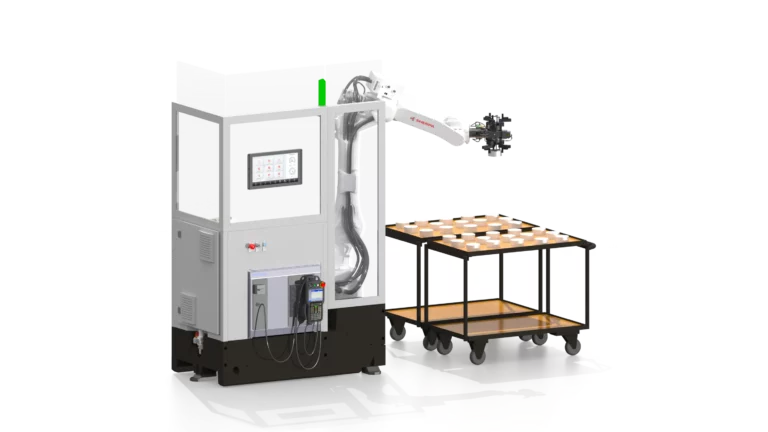

Robots without cameras are blind. Workpieces must be precisely positioned for the robot to pick them up. Typically, integrated fixtures or stationary setups like grid plates, rotary tables, stackers, or towers are used for this purpose. The SherpaLoader®, however, operates without expensive and error-prone mechanical systems. It utilizes a 3D camera and laser system to detect the position of workpieces on the material staging device. Just like in living beings, "eyes" increase the flexibility of robots.

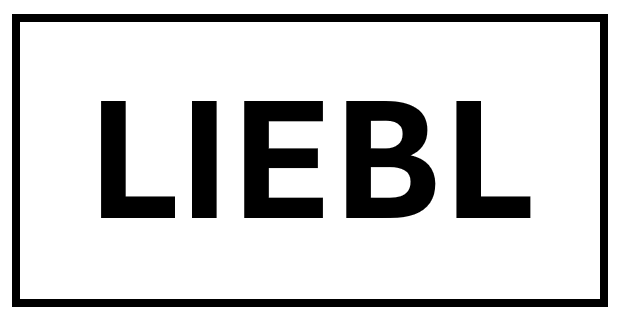

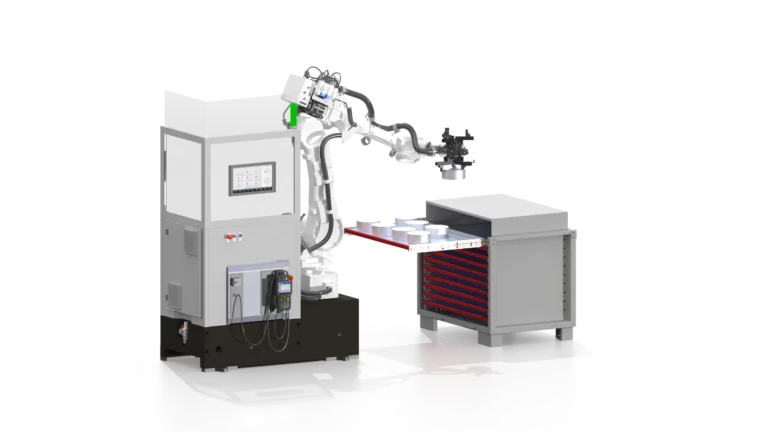

With conventional loading systems, you must choose one type of material staging. Conveniently, the SherpaLoader® is designed to handle three types: table trolleys, pallets, and SpaceBox drawers. The most suitable option is determined by your use case, i.e. the number, weight and size of your workpieces.

Learn more

For batch sizes ranging from 5 to 5,000 workpieces, short setup and changeover are critical. Because during that time, the production machine is idle, and valuable spindle time is lost. For camera-guided systems, retooling grid plates, magazines, or other mechanical stops becomes unnecessary; only the width of the robot grippers needs to be adjusted. Camera-guided systems offer much shorter changeover times than mechanical systems.

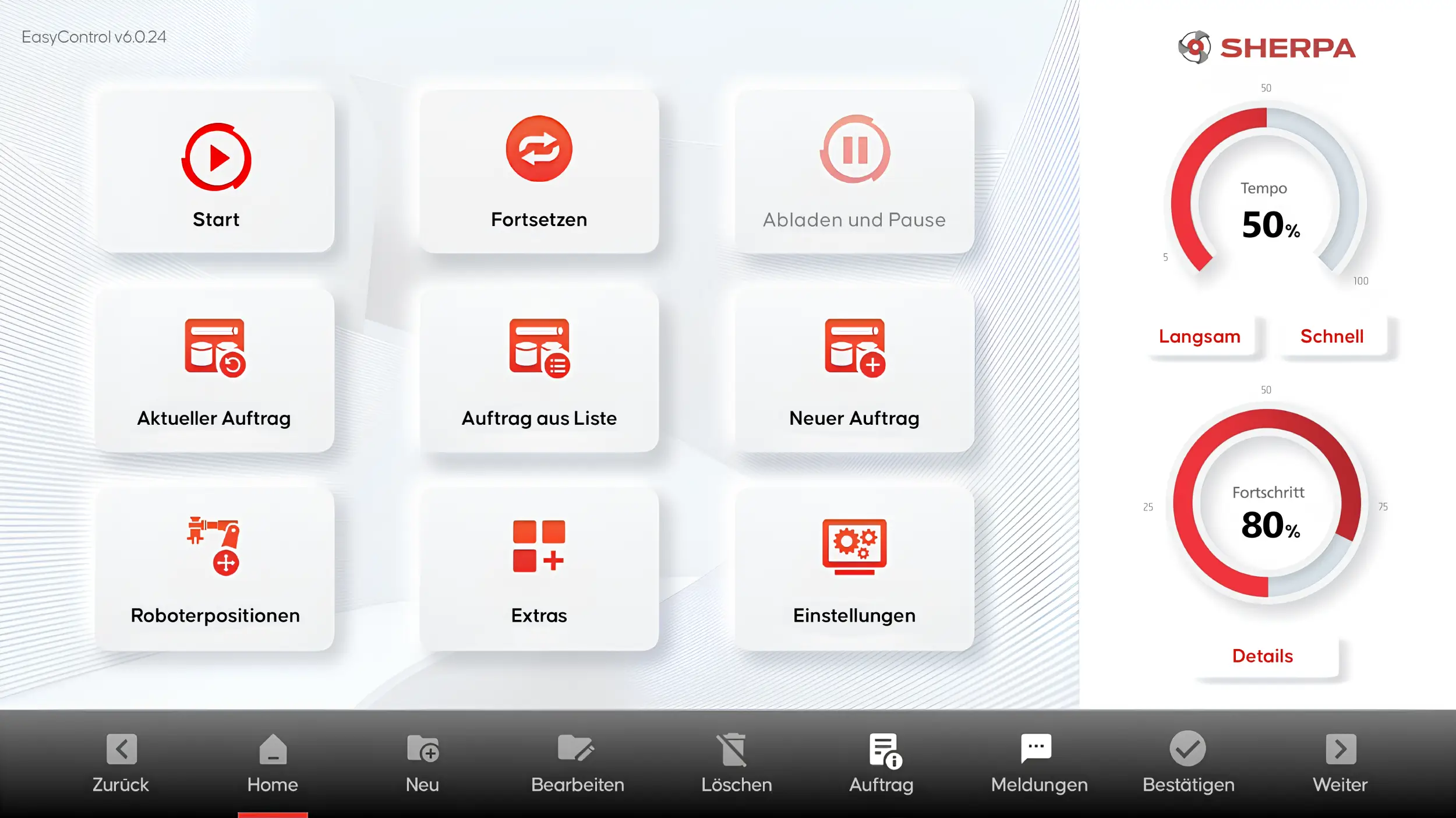

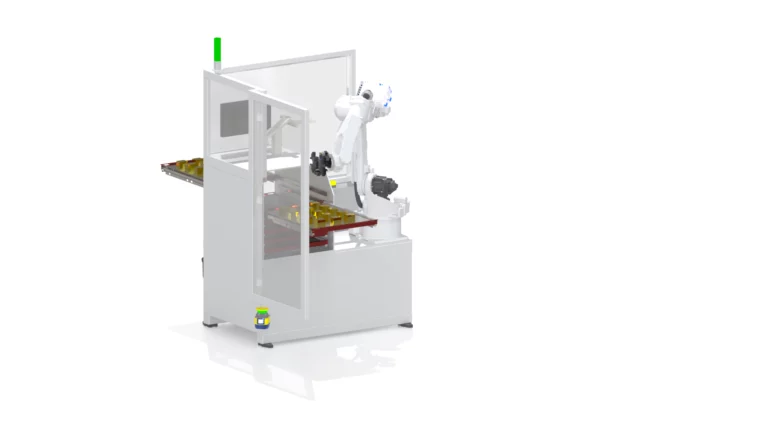

The robot cell is operated via an easy-to-use dialog-based control system with a graphical user interface. Using a 17" touch display, operators can quickly set up new jobs—without any knowledge of robot programming. Clear symbols and intuitive input screens provide context-sensitive guidance, making job setup straightforward and efficient for technical staff.

The movements of the SherpaLoader® are fine-tuned for loading machine tools. During commissioning, all robot paths are adjusted to match both the geometry of the production machine as well as the dimensions of workpieces. This ensures the automation is fully configured and ready for use before handover. The SherpaLoader® allows medium-sized manufacturing companies to utilize robot cells without the need for full-time robotics experts for occasional setup tasks.

These companies are already automating their production with MAFU-SHERPA CNC Automation GmbH

Customer Success

„Aufgrund des kurzen ROI haben wir gleich die zweite CNC-Automation von MAFU-SHERPA gekauft. Und wir planen in Zukunft weitere Maschinen zu automatisieren.“

Matthias Rose, Managing Director

Reduction in

personnel costs

additional

CNC machines

per operator

"The robot has more than doubled revenue of our automated cnc machine. This is both a success and a motivation for us. That's why we've just invested in a new machining center from HERMLE – and another SherpaLoader."

Johannes Seilbeck, Managing Director

Daily increase in

spindle time

Revenue growth of

automated machine

"At our Gebesee location, qualified machine operators are scarce. Improving delivery reliability was possible only with the support of a robot."

Rene Liebl, Owner

unmanned

production time

Additional

skilled workers

required

At the prestigious Handling Award 2021, the jury and readers honored the SherpaLoader® with two accolades: 1st place in the category "Handling & Assembly" and the title of "Best Product" in competition. Thank you for your vote!

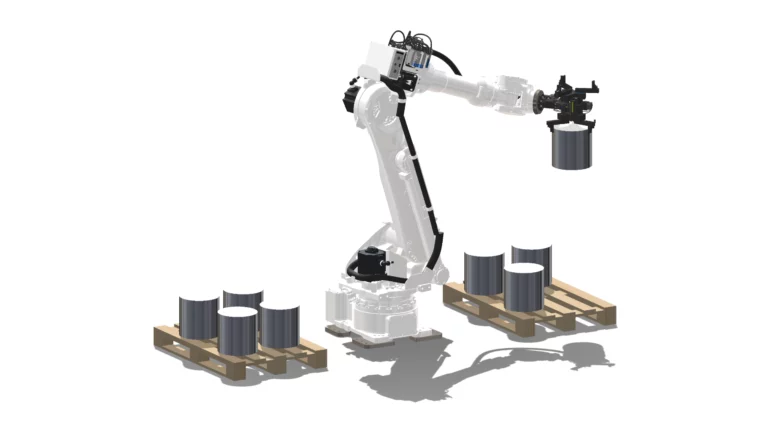

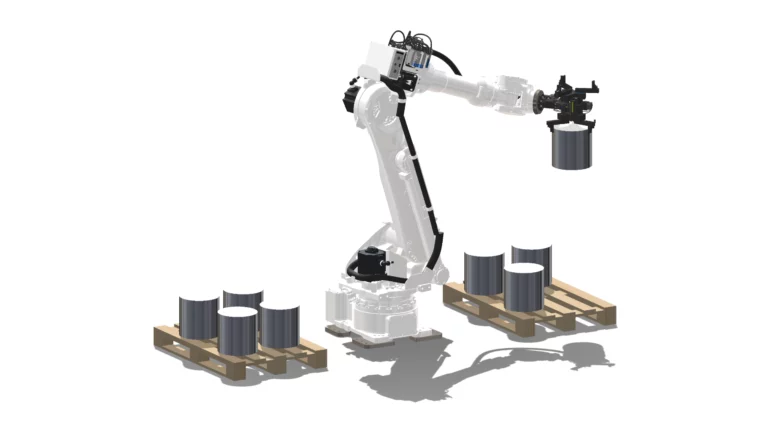

Robots with a payload of 7 to 225 kg for handling round and hexagonal bars, plate and square blanks as well as cast and forged parts. Equipped with two-jaw parallel grippers or three-jaw centric grippers, pneumatically or servo-electrically operated, equipped with single fingers, pendulum jaws, contour jaws or prism inserts.

For edging material

Max. weight*: 4 kg

Workpiece range:

10 x 10 x 10 to

150 x 150 x 150 mm

For edge material

up to 8 kg weight*

in the size range

10 x 10 x 10 to

150 x 150 x 150 mm

For edging material

Max. weight*: 18 kg

Workpiece range:

20 x 20 x 10 to

200 x 200 x 200 mm

For edging material

max. weight 38 kg

Workpiece range

20 x 20 x 10 mm to

300 x 300 x 300mm

For edging material

max. weight 73 kg

Workpiece range

20 x 20 x 10 mm to

300 x 300 x 300 mm

SherpaLoader For edge material

up to 175 kg weight*

in the size range

project-specific

For cylinders and shafts

max. weight 4 kg

Workpiece range

Ø 10 x 10 - Ø 150 x 150 and

Ø 10 x 50 - Ø 30 x 300 mm

For edge material

up to 8 kg weight*

in the size range

10 x 10 x 10 to

150 x 150 x 150 mm

For cylinders and shafts

max. weight 18 kg

Workpiece range

Ø 15 x 10 - Ø 220 x 200 and

Ø 10 x 100 - Ø 60 x 400 mm

For cylinders and shafts

max. weight 38 kg

Workpiece range

Ø 20 x 10 - Ø 300 x 300 and

Ø 20 x 200 - Ø 80 x 600 mm

For cylinders and shafts

max. weight 73 kg

Workpiece range

Ø 20 x 10 - Ø 300 x 300 and

Ø 20 x 200 - Ø 80 x 1.000 mm

For edge material

up to 175 kg weight*

in the size range

project-specific to

project-specific

Grows with your needs: functional expansions for modular

integration, tailored to your production requirements

Featuring a universal interface, the SherpaLoader® can be connected to any standard turning or

milling machine, regardless of age. This allows the same SherpaLoader®

to retrofit an older machine or automate a new one with ease.

We're excited to show how your operators can set up and start the automation without any instructions.

Call us:

+49 711 2525 744 - 0

Email us: