Optimized work processes,

increasing staff efficiency

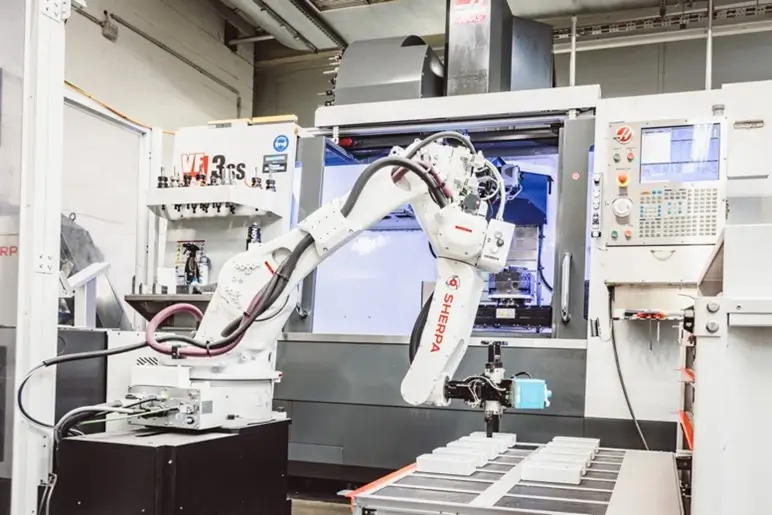

ROLEC, a leading manufacturer for the housing of industrial devices, has boosted production efficiency through the use of SHERPA robots.

With roots dating back to the 1960s, founder Friedhelm Rose revolutionized the industry by developing the world’s first sealed aluminum housing. Since then, the family-run company has continually evolved, becoming a top producer of HMI enclosures and support arm systems. The innovative spirit of Friedhelm Rose lives on today, leading to groundbreaking products such as the profiPLUS support arm system and the aluDOOR series, which won the German Innovation Award in 2023.

All ROLEC housings are produced using cutting-edge machinery. Precise CNC techniques drill or mill fine tolerances and custom cutouts to meet individual requirements, effortlessly fulfilling even complex machining demands.

Before Automation

The production of custom aluminum housings for electrical and electronic components was labor-intensive.

Some of these aluminum housings were processed on HAAS VF-3SS machines, using a mechanical four-jaw chuck from HWR to prevent clamping marks on the thin-walled geometry and ensure ROLEC’s premium quality promise. However, the machining centers lacked media union on the fourth axis to operate the clamping device.

Although production processes were stable, machine operators often worked elsewhere during long production runs. When the machining program finished, the spindle regularly sat idle until an operator noticed the end, cleaned the finished part, and restocked the machine. To address this, the production team aimed to increase staffing efficiency and maximize spindle uptime. The technological challenge was automating the proven clamping technique without altering the established process.

The Solution

The answer came in the form of a SherpaLoader® M25 with an electric spindle drive. Tasks were redistributed: continuous material staging and supply were handled by trained employees, allowing skilled machinists to focus on production quality and automation.

In the new process, a SpaceBox is loaded with raw material. After completing the current job, the operator replaces the SpaceBox with a new one using a pallet jack, so production resumes immediately. Alternatively, the SpaceBox can remain in place while processed parts are swapped for new raw materials. The operator selects the next job in the dialog control system, and the robot takes over: picking up parts, placing them in the pre-stamping station, and then into the machine vise. The workpiece is clamped by a torque wrench mounted on the robot. Finished parts are automatically cleaned with compressed air and placed back into the SpaceBox by the robot.

A key challenge in the automation process was preventing clamping marks. The gripper’s clamping force was applied through four polyurethane inserts, specially tailored to this application during the project phase, ensuring that ROLEC’s premium quality was maintained throughout automation.

With around 70 housings in the SpaceBox, the system is designed to never sit idle waiting for an operator. Staffing requirements on the automated machines have been reduced by more than 50%, providing a significant competitive advantage and freeing up employees for other tasks. Additionally, the ability to run unmanned night shifts with the robot producing output has reduced the ROI to less than two years.

Matthias Rose, Managing Director:

“Our operating costs are heavily dependent on personnel. Therefore, our goal was to enhance the productivity of our skilled and experienced workers. Today, our employees manage two additional production machines. Due to the short payback period, we quickly purchased a second CNC automation from SHERPA. And we plan to automate more machines in the future.”