Successful Entry

into Robotic Automation

Industrial Precision Technologies GmbH, Heilbronn – IPT – specializes in…

IPT – Industrielle Präzisions-Technologien GmbH, Heilbronn, specializes in the precision machining of individual components, prototypes, and small production batches using state-of-the-art machining centers in a climate-controlled environment. The company’s core competencies include the processing of complex geometries, high-precision 5-axis multi-sided machining, and comprehensive documentation of ultra-tight tolerances—all of which is particularly important for satellite technology applications.

When a key customer of IPT’s significantly increased order volume, IPT was faced with a critical challenge: How to economically automate the existing 5-axis DMU 60 eVo machining center?

The Challenge

As a contract manufacturer, IPT must plan its investments strategically and pursue economically viable solutions. An inquiry with the machine manufacturer revealed that the required retrofitting for automation—including rotary feedthrough on the 4th and 5th axes, hydraulic clamping systems, an automated machine door drive, and a Profibus automation interface—would have involved a high five-figure investment. Given that the machine had already been in operation for ten years, this was not a viable option. IPT therefore sought a needs-based alternative—and found it with SHERPA Robotics.

The Solution

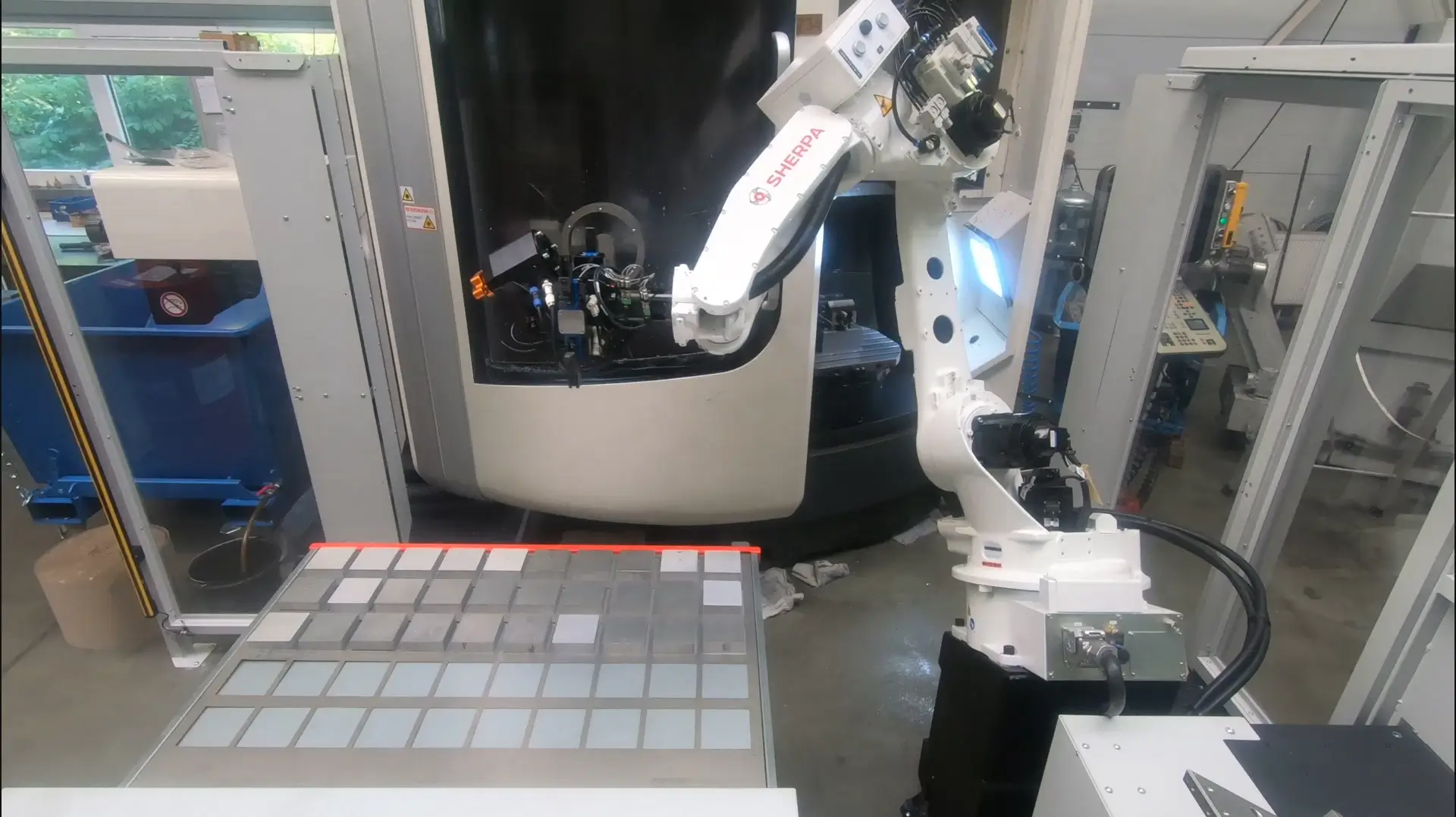

Instead of pursuing costly machine modifications, IPT opted for the tailored automation solution SherpaLoader® M25:

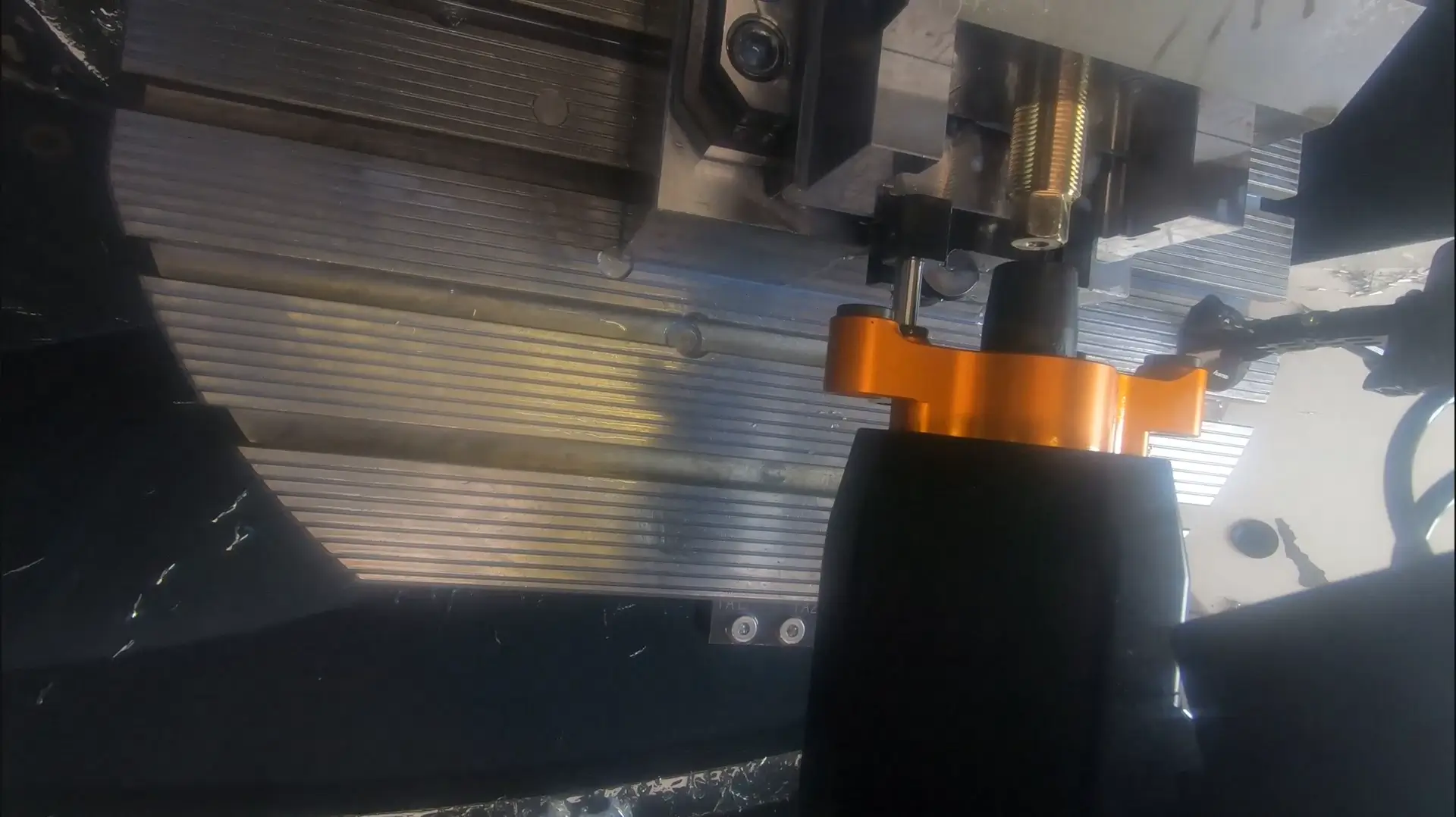

- For machining centers without rotary feedthrough, SHERPA integrates the RoboBuddy electric spindle drive by ALLMATIC to enable efficient automation of mechanical vises. This eliminates the need for retrofitting a hydraulic clamping system.

- SHERPA provided a customized I/O interface, retrofitted at less than half the cost of a Profibus interface from the original machine manufacturer. This enabled a cost-efficient and flexible integration of automation components.

- The existing round door of the machine was equipped by SHERPA with a safe, automated door drive, seamlessly integrated into the production process.

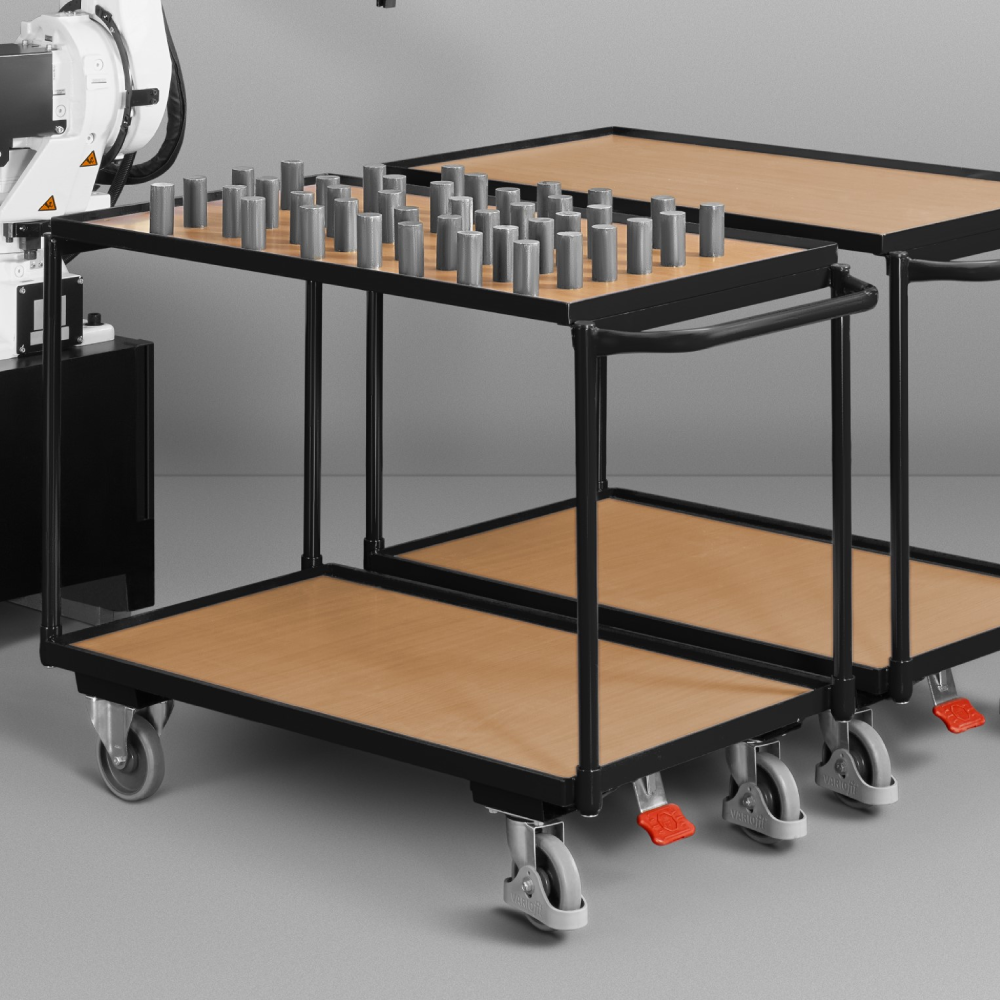

- With SHERPA’s SpaceBox, more than 500 workpieces can be staged on the footprint of a standard Euro pallet. This allows the system to run autonomously for over 8 hours without operator intervention.

Holger Gräbeldinger, Managing Director

“We commissioned the SHERPA automation solution approximately nine months ago. Today, I can’t imagine how we would manage the workload of the automated system with manual loading.”

Thanks to SHERPA, IPT was able to implement a cost-effective automation solution without the need for expensive machine modifications—an essential step toward greater efficiency and enhanced competitiveness.