Improved delivery reliability

with the same team of operators

CNC-Fertigungstechnik Liebl

specializes in manufacturing precision parts of special-purpose machine. Located in Gebesee, a village of 2,000 residents in the Thuringian Basin, the shortage of skilled labor is especially evident. In 2023, 49.5% of all open positions in the area lacked qualified applicants, and projections for 2035 show little improvement.

The goal of owner Rene Liebl is to secure local production in Gebesee by decoupling production throughput from staffing levels, allowing short-term orders to be fulfilled regardless of personnel availability.

Before Automation

Fluctuating demand was, and still is, central to the daily business. Planned orders often don’t match reality. Customers, especially with urgent requests, expect deliveries within a few days or even immediately after the weekend. For rush orders, no operators were available to work late or night shifts.

The Solution

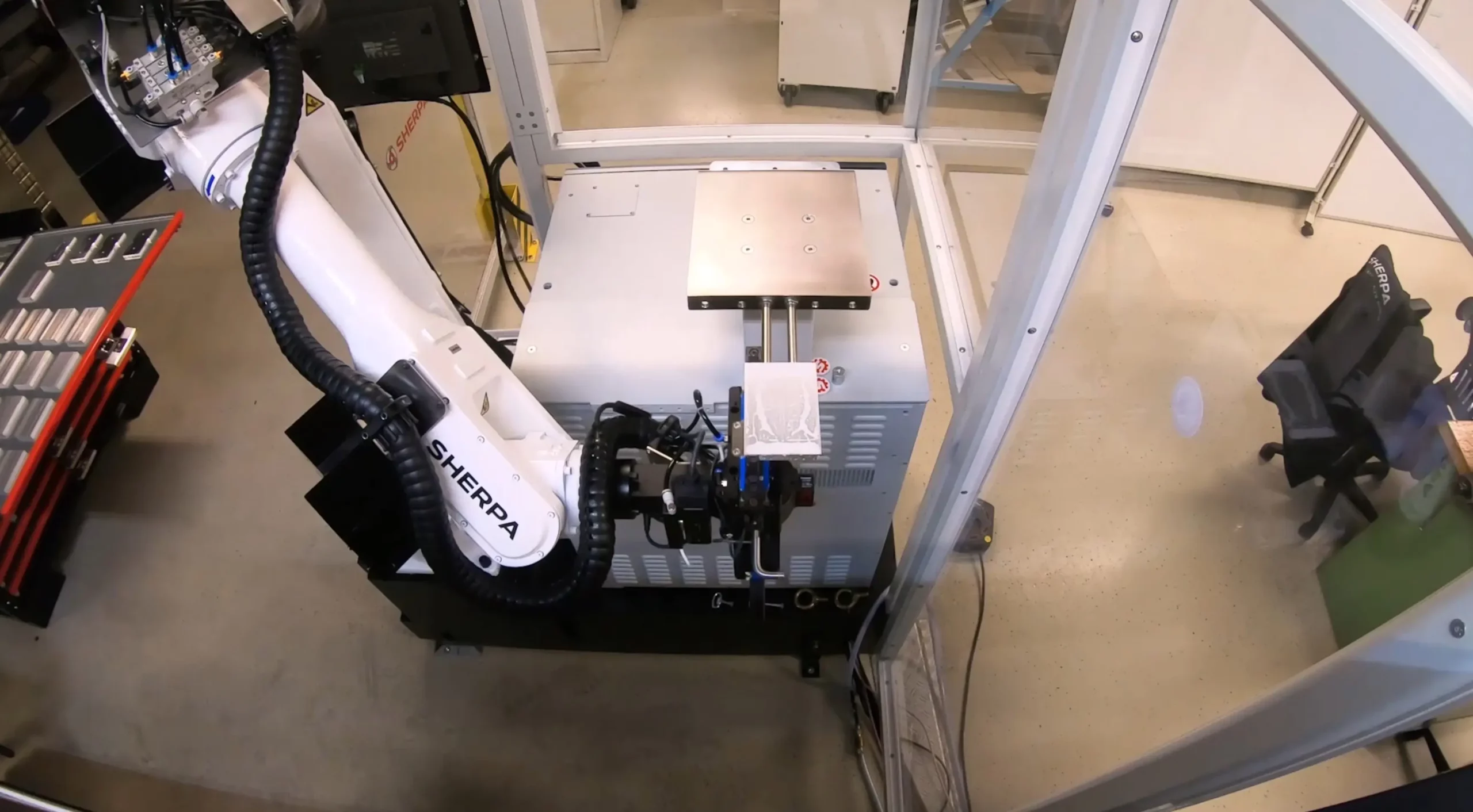

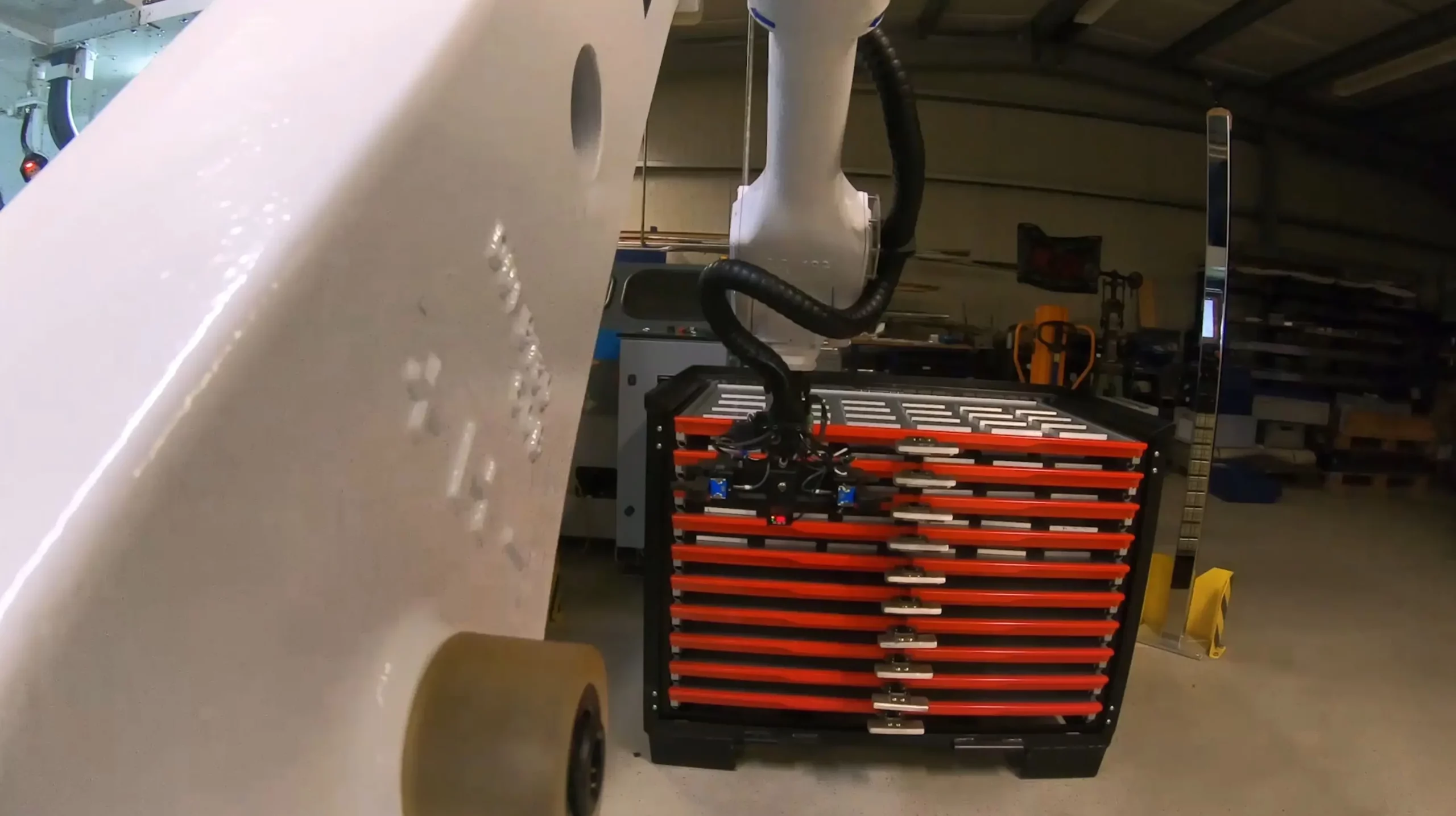

was a CNC automation that works even when the operators have gone home. The challenge was to automate a vertical MAZAK machining center, model VCN-530C. The machine was retrofitted with a robot interface and two pneumatic clamping devices. The robot control system manages the clamping device, minimizing retrofitting costs. To further extend autonomous runtime, the SherpaLoader® was equipped with a repositioning station, allowing both the front and back sides of parts to be processed in one run.

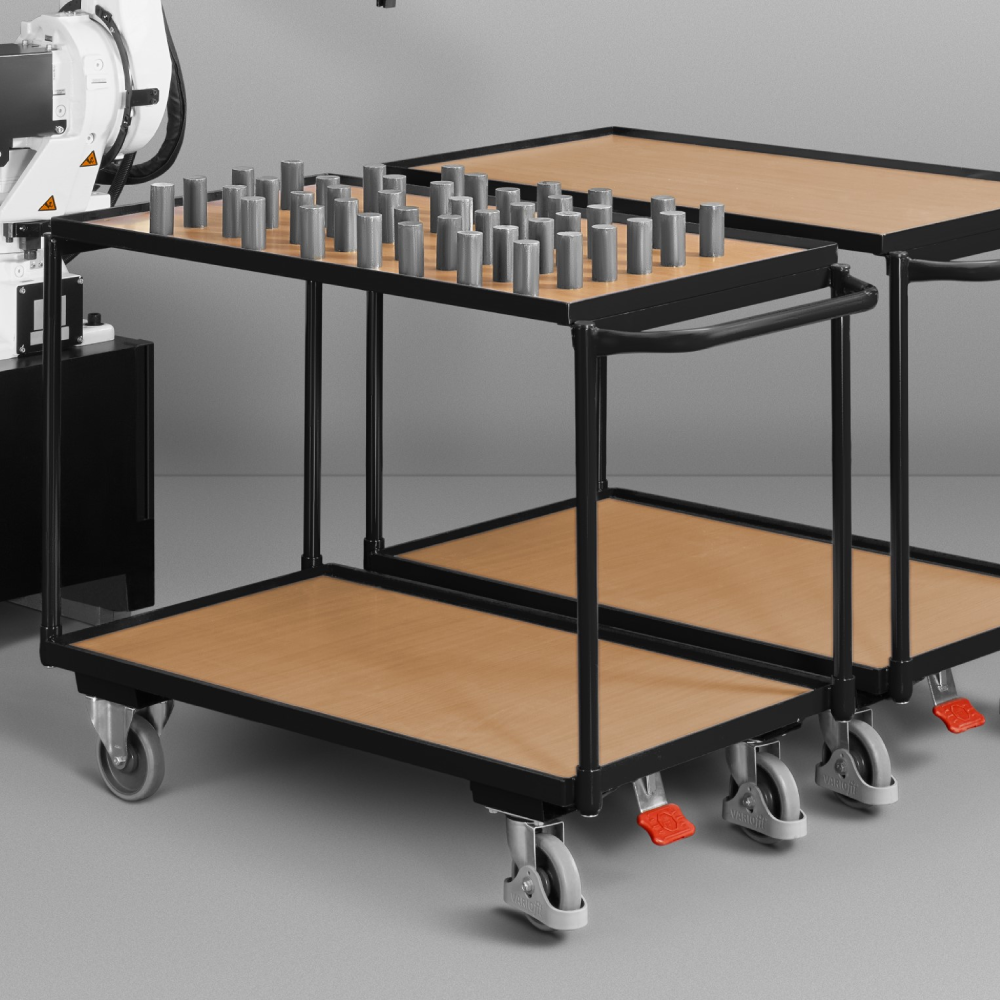

The SpaceBox, serving as the storage unit for material staging, holds over 400 raw parts measuring 60 x 100 x 35 mm, enabling more than 60 hours of autonomous operation.

Without incurring additional shift premiums, a robot now handles rush orders overnight or series production over the weekend, ensuring parts are ready for delivery by the next working day.

Operators are not only relieved of night shifts, but also benefit from easier order preparation: Raw material is no longer picked by machine operators but by warehouse staff. By decoupling logistics and production, material is now prepared in the warehouse, rather than in front of the machine.

The secret to productivity lies not in speed but in the stability and consistency of operations. While an operator can only work one shift, a robot can run up to three—without breaks and at a constant speed. For suitable orders, the robot operates 100 hours per week or more.

Rene Liebl, Owner:

“At our Gebesee location, qualified machine operators are scarce. Improving delivery reliability was possible only with the support of a robot. Simply put, we can’t afford not to automate our CNC machines!”