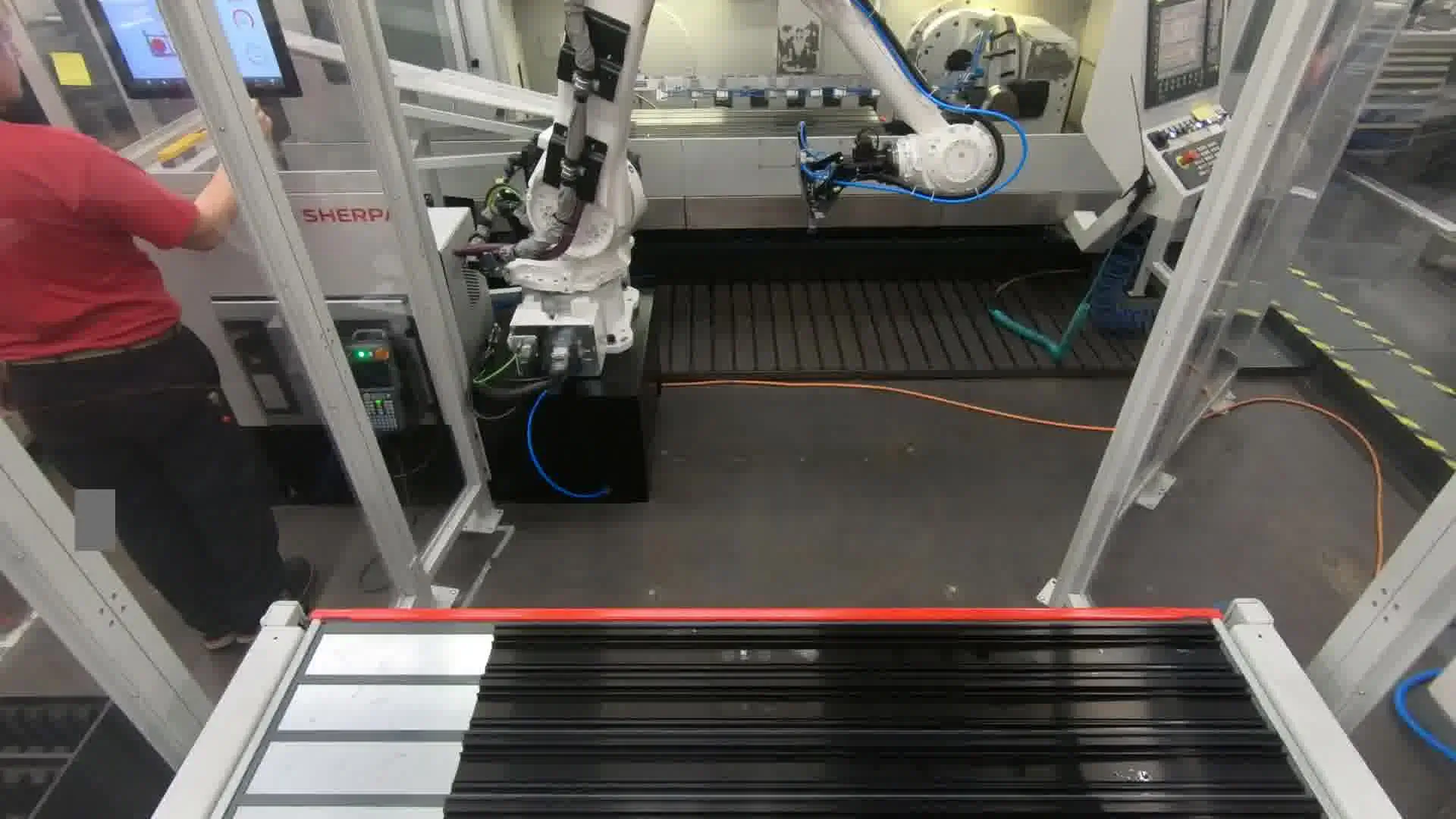

Automation of a Spinner 4-axis CNC machine

When implementing automation solutions in the manufacturing process, specific requirements must be taken into account in order to increase productivity. The integration of the SherpaLoader® into this process illustrates how coordinated technologies can meet these requirements and optimize the production process.

The integration of the SherpaLoader M50 in a Spinner 4-axis CNC machine brings a significant increase in efficiency in the manufacturing process of aluminum profile rails. The SherpaLoader M50 has been given a vacuum suction device adapted to the application, which was specially designed for the gentle and precise handling of aluminum profile rails. This technology enables the robot to grip the profile rails securely and place them on a pre-positioning tray, where the component is pressed precisely against a stop to ensure alignment in the X and Y axes.

A critical factor in the application is the precise and gentle handling of the workpieces in order to ensure their quality and maximize the efficiency of the processing process. The SherpaLoader® uses the specially developed vacuum suction device, which not only clamps securely, but also positions the workpieces precisely for further processing. This process eliminates the risk of damage to sensitive materials.

Before inserting raw parts, the robot cleans the clamping device of the Spinner CNC machine with a compressed air nozzle to remove residues such as coolants, lubricants and chips, minimizing potential sources of error. The robot then positions the component in the clamping device, which closes automatically, as do the motor-driven doors of the processing machine.

Adaptation to different workpiece shapes and production requirements is another crucial point. The SherpaLoader® answers this need by integrating advanced camera-based recognition technology. This makes it possible to switch between different component geometries without time-consuming manual changeovers, which significantly increases flexibility in the production process and makes it possible to react quickly to changing production conditions.

One aspect of the process is the preparation of the next workpiece by the SherpaLoader while the machine is still processing the current component. This parallel work helps to reduce idle times and maximizes the spindle time of the processing machine.

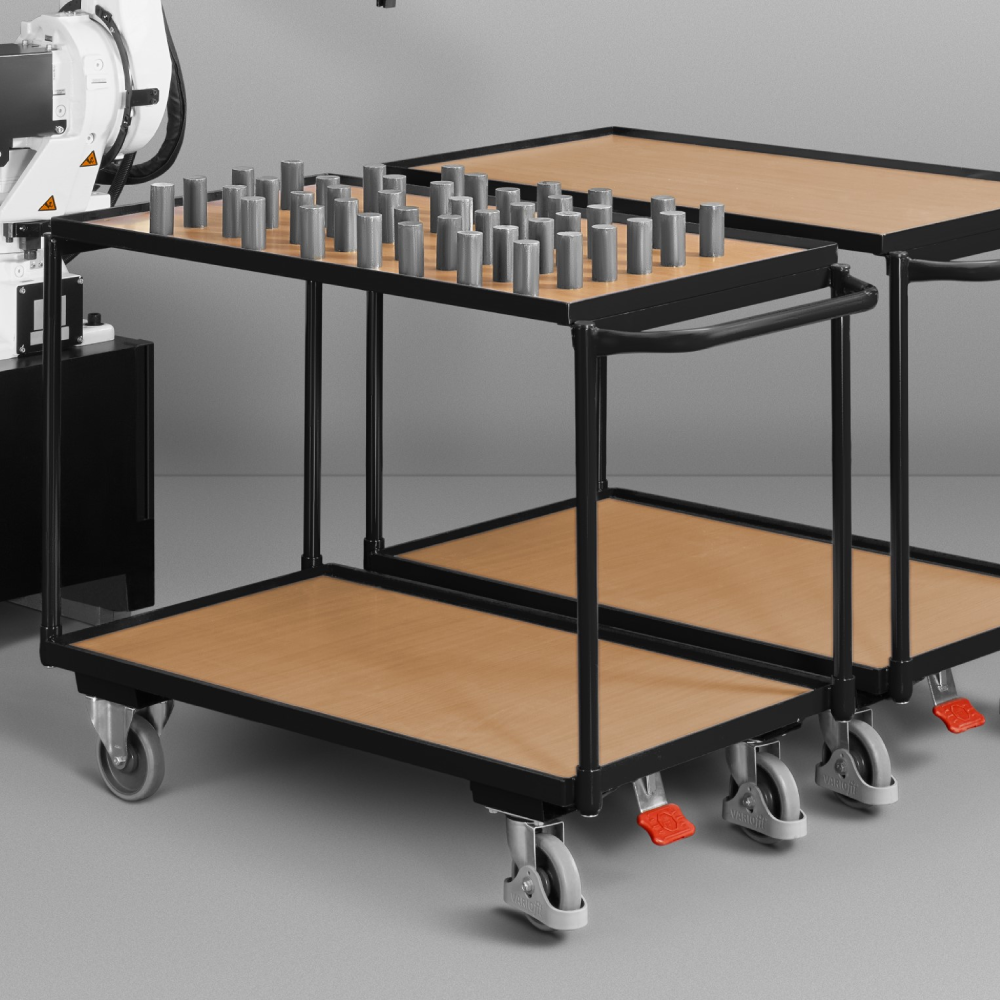

Once machining is complete, the finished component is cleaned with a blow nozzle and removed by the robot to place it on the positioning slide and grab the new blank for the next machining step. The finished parts are then transferred by the robot to the Spacebox, a specially designed supply device with ten drawers, each of which can hold up to seven components.

In summary, the SherpaLoader® offers a comprehensive solution for automation in the use of CNC machines. By taking into account a wide range of customer requirements and technical challenges, the SherpaLoader® helps companies to achieve their production goals efficiently and safely, always meeting the highest safety standards.